Worker Exposure to Hazardous Chemicals - Minimize or Eliminate?

Written By: Atanu Das on Thursday, February 1, 2018

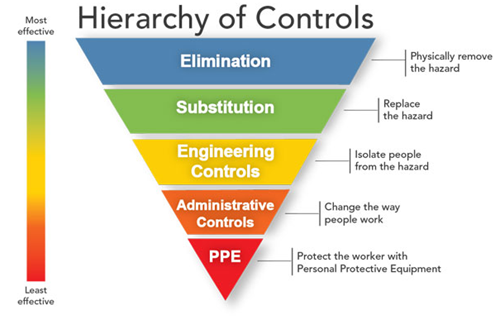

In the OSHA Hazard Communication Standard, the agency has emphasized the need for worker protection. Specifically, all employers should prioritize controlling exposure to chemical hazards and toxic substances. The agency suggests using a hierarchy of controls when determining how to do this. It can be visualized as follows:

Where possible, elimination or substitution is the most desirable followed by engineering controls. Administrative or work practice controls may be appropriate in some cases where engineering controls cannot be implemented or when different procedures are needed after implementation of the new engineering controls. Personal protection equipment is the least desirable but may still be effective.

Some examples of the types of control may include:

Elimination/Substitution:

Substitute the chemical with a safer alternative.

Engineering Controls (with physical changes in the workplace):

Change the process to minimize contact with hazardous chemicals.

Isolate or enclose the process.

Use fume hoods.

Administrative and Work Practice (with modified procedures):

Rotate job assignments.

Adjust work schedules to keep worker minimally exposed.

Personal Protective Equipment:

Respiratory Protection/Gloves/Eye protection

While elimination and substitution are highly desired as the most effective means of hazard reduction, this remains the most difficult to design in most existing processes. However, using a chemical inventory system, it may be possible to find safer alternatives in your operations. You could start by asking if there are chemical alternatives that have been implemented in similar applications or maybe find other businesses also seeking safer alternatives for the same chemical and collaborate to find a solution.

Most workplaces develop engineering controls to control exposure by removing the hazards at the source, before it comes in contact with the worker. This may be done with improved ventilation, process enclosures, or other control techniques.

When hazards are least controlled and all of the other above means are not feasible, administrative controls and PPE are used as the lowest control measure. These may be relatively inexpensive to implement, but in the long run prove costly to sustain.

Contact us for assistance with your chemical hazard plan.